Start the New Year Right: The Ultimate Checklist for Preparing Your Business’s Grooming Tools

Happy New Year, grooming professionals! As we usher in another year of grooming, clipping, and...

Do I need pay to have my scissors maintained professionally or can I do it myself?

I’m glad you asked! I want to show you a pair of scissors that came to my shop because they were no longer cutting. On inspection, the edges were still fairly sharp, but the reason they weren’t cutting was much more basic.

Whenever a pair of scissors comes in for sharpening the tension screw, washers and any tension springs that are in the pivot point of the scissor are thoroughly inspected.

After an initial inspection, the scissors are disassembled to ensure that all inside parts of the pivot are in good working condition. We have come across a lot of scissors over the years with disintegrated washers, missing tension springs or even stripped tension screws. These small pieces are integral for maintaining optimal performance of your scissors. This is a standard procedure for professional sharpening services.

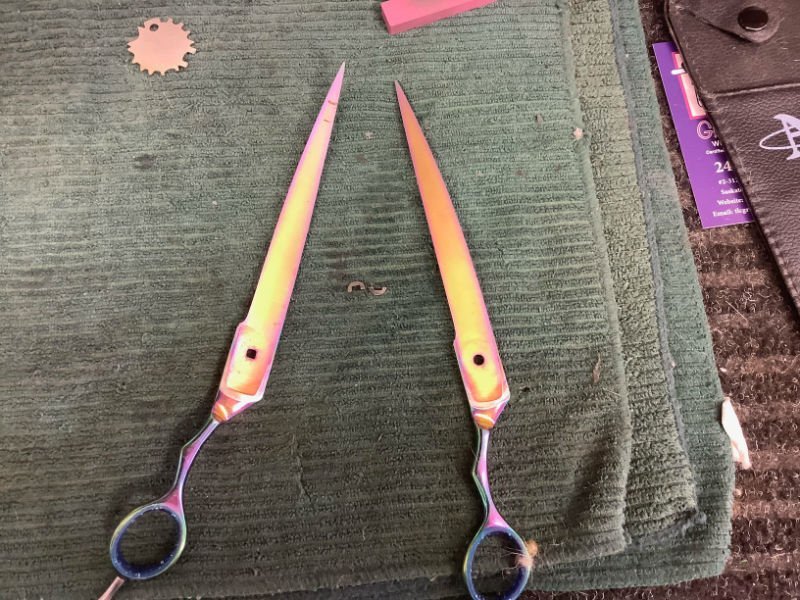

Here are the scissors that came in to my shop. As you can see in the picture above the tension spring of this scissor has broken in half. When these springs break they generally will not hold tension in your scissor which means the scissor will become loose while using and won’t cut hair efficiently. This in itself can explain why the scissors weren’t performing.

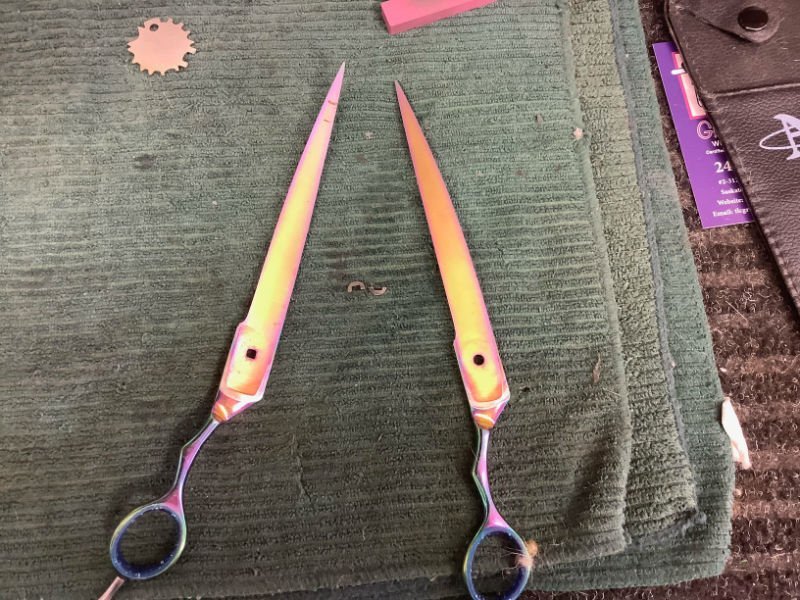

Pictured above is the broken tension spring and a brand new tension spring. Tension springs that require changing are free of charge as part of our servicing program. Once these scissors were taken apart and the tension spring replaced, I cleaned and lubricated them, and precision sharpened them before putting them back together. One final cutting test and they were ready to go back to work.

Not all scissors have tension springs in them as some just have washers. These will also break down over time especially if there is no scissor oil/lubrication applied on a regular basis.

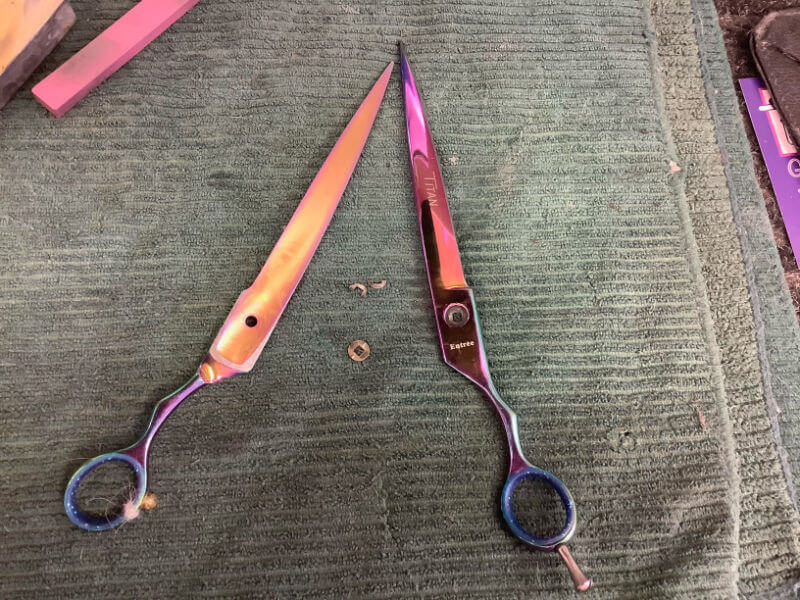

Here are another pair of scissors that came in on the same day.

The photo above shows a disintegrated plastic washer. We also replace these free of charge as part of our service program.

The photo above shows a tension screw which has rusted, common when working in a humid environment. You can avoid this happening by oiling or lubricating the tension screw at the end of every work day. It doesn’t take long to do and will ensure longevity in the life of your grooming tools.

You’ve invested good money into your grooming tools so it’s important to ensure they will continue performing well.

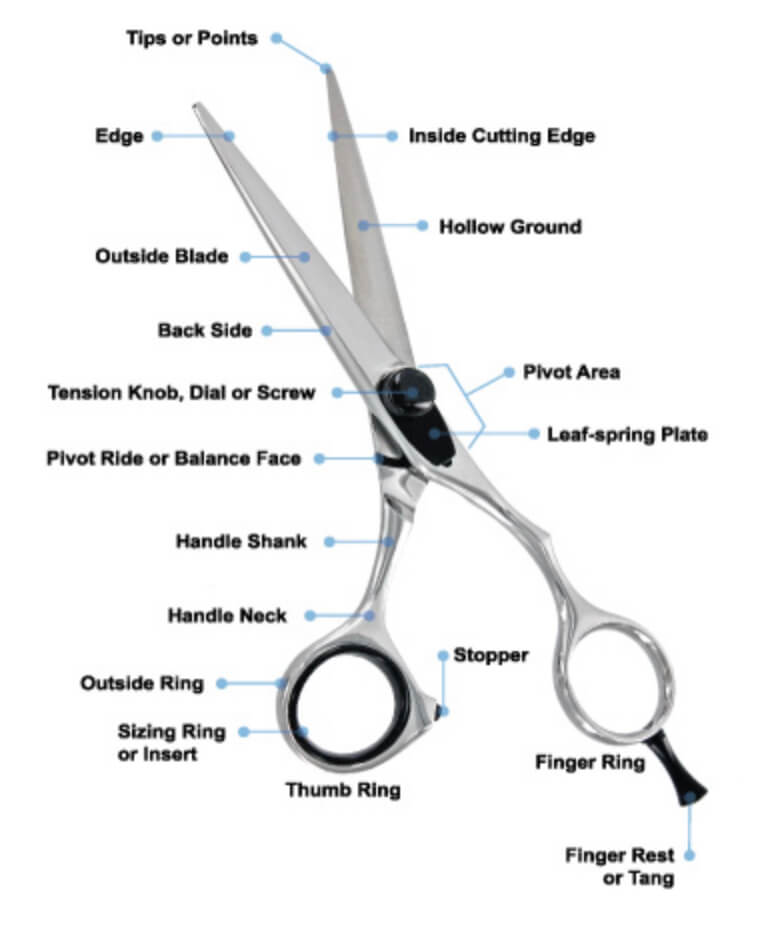

In case you’re curious, and if you’ve come this far in this post then I know you are, the following drawing details all the parts of your dog grooming scissors. When you know your scissors you can better understand how to take care of them, and in some cases, how to hold them correctly to get a precise cut every time.

General scissor sharpening and maintenance ranges between $12-$30 depending on the type of scissor and type of edge.

If you think you need to replace a pair of scissors, give us a call first. Maybe all they need is a bit of maintenance and sharpening to bring out their best work. If they’re too far gone, you can purchase top quality scissors here.

Read the last post about blaster maintenance and repair and why regular attention is critical to your safety in your work environment.

Sherry

Call me at the shop! (780) 916-6309

Join the list and be the first to know about new products and promotions.

Happy New Year, grooming professionals! As we usher in another year of grooming, clipping, and...

When it comes to choosing grooming tools, the options can be overwhelming. How can you...

Find out how backup equipment keeps your business operations flowing smoothly when your main tools...

In this guide, we'll shed light on 8 unmistakable signs that it's time to give...